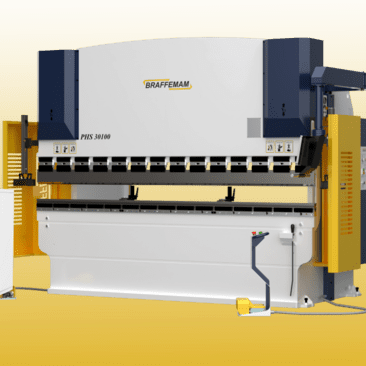

Braffemam launches bending machines with innovative automatic compensation technology

In this edition of Intermach, Braffemam presents innovations that raise the industry standard: the launch of synchronized bending machines with automatic compensation and its new CNC software, developed for machines with an axis stabilization system.

These new features are the result of intense engineering work, conducted by a highly qualified team, always focused on improving the usability and efficiency of the equipment. With this, Braffemam reaffirms its commitment to offering cutting-edge technology to operators throughout Latin America.

Technological innovations highlight Braffemam in the sheet metal cutting and forming sector, with high-performance and energy-efficient equipment. With a portfolio that includes bending machines, lasers, guillotines, baling presses, among others, the company has positioned itself as a strategic partner for industries that seek quality, productivity and innovation for over 37 years.

The company stands out for the quality and sophistication of its machines, which are designed and built in Brazil to provide high productivity, sustainability and resource savings to the entire Latin American market. Braffemam’s innovations are not only a reflection of quality, but also of the search for solutions that make Brazilian industry more competitive on the global stage.

INNOVATIONS AND MACHINES DIFFERENTIALS

In the PSB line we have bending machines with automatic compensation and synchronized, which automatically adjust to the bending process, guaranteeing precision and quality. With our exclusive closed-loop reading system, combined with Axes Y1, Y2, R, Z1 and Z2 controlled via CNC, we drastically reduce operational errors. This system is ideal for companies that seek agility and precision in bending processes.

Another major difference between Braffemam machines is the use of a soft starter, which is included in both the synchronized CNC line and the line with a stabilizer axis. This starting system reduces energy consumption and reduces energy peaks in your network, and can also keep equipment on standby when not activated for a programmed period of time, saving energy and contributing to sustainability.

By developing its machines with cutting-edge technology, Braffemam ensures that maintenance is simple and quick. The company implements advanced monitoring systems in its interface, to facilitate fault detection and reduce downtime. Furthermore, the machines are designed to operate with high productivity, maintaining quality and precision over long periods of use, meeting the demands of the most demanding industries.

ABOUT BRAFFEMAM

With more than 37 years of history, Braffemam is a national company specializing in the manufacture of machines for cutting and bending metal sheets. The company offers advanced technological solutions, developing and producing 100% national equipment for various industrial segments. With more than 2,500 machines sold throughout Brazil and South American countries, Braffemam has established itself as one of the market leaders, always committed to innovation, quality and sustainability.

The company has a solid reputation for providing equipment that serves a wide range of industries, such as the metallurgical, automotive and construction sectors. With a vision focused on national technology, the CNC and Braffemam’s own software are the results of continuous research and development work, aimed at meeting the specific needs of cutting and forming sheet metal, with a focus on reducing costs and increasing competitiveness of its customers.